Chapter 3

Bandsaw Blades

(and How to Fold Them)

Chapter 5

Machinery Checks

and Fine Tuning

Chapter 7

Ripping Rough Stock

Chapter 9

Resawing

Chapter 11

Cutting Circles

Chapter 13

Making Templates

Thoughts on

Woodworking

Part 2

Buy the Right

Lumber Thickness

Instructional Woodworking

DVDs

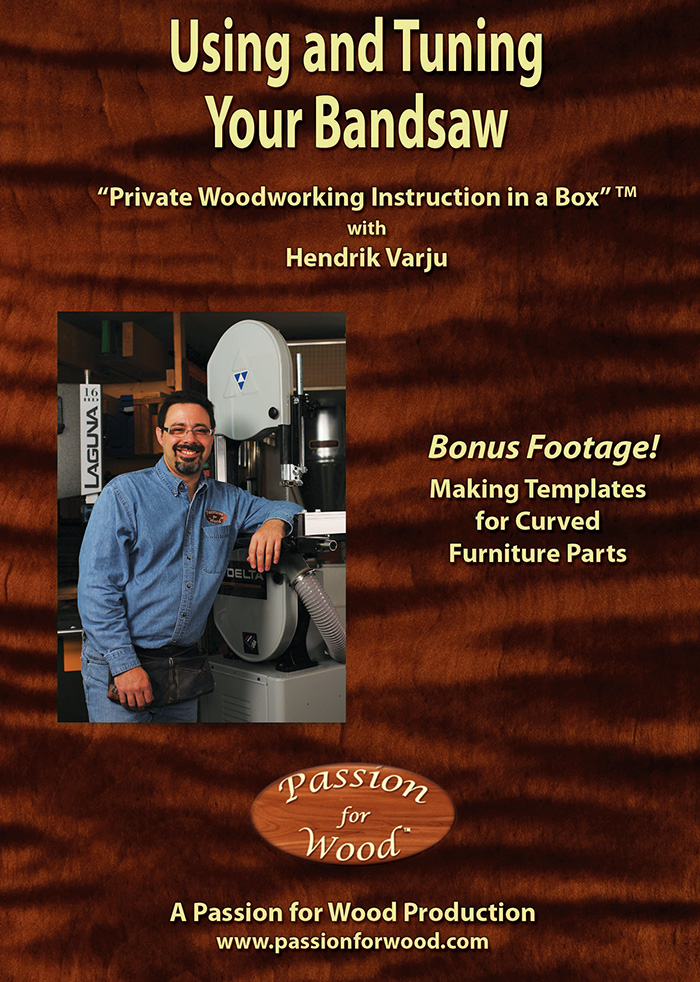

Using and Tuning Your Bandsaw

Author: Hendrik Varju

Hendrik Varju / Passion for Wood / September 2011

ISBN: 978-0-9781432-8-2

7 hours, 54 minutes on 4 DVDs

Price: Cdn. $94.95 + applicable taxes

+ shipping and handling

Ontario residents pay 13% hst. Canadian residents outside of Ontario pay hst at their own province’s rate, or 5% gst if in a non-participating province. Residents outside of Canada pay no tax.

To view a clip of this DVD click the play button above.

The above video clip has been reduced in quality for online viewing. The real DVD product has a much higher resolution.

![]()

To download a PDF of this production’s

Table of Contents click here.

This document will make it easier for you to navigate the video.

The Table of Contents is already included inside the DVD case, but you can download a copy here if you’ve misplaced it.

After many successful instructional DVDs — see “Jointer and Planer Secrets”, “Revelations on Table Saw Set-up & Safety”, “Working with Plywood”, “Wood Science & Design”, “Surface Preparation and Staining” and “Hand Finishing and Rubbing Out” — Hendrik decided to turn his attention to the world of bandsaws and routers, releasing two new productions in 2011. “Using Your Router and Router Table Safely” is the second DVD newly released in 2011, but let us first hear about the long awaited bandsaw production: “Using and Tuning Your Bandsaw”.

“Using and Tuning Your Bandsaw” takes you through everything you need to know to successfully use and tune up your bandsaw, all spread over nearly 8 hours of footage on 4 discs. As is Hendrik’s usual style, this DVD set is a detailed step-by-step course – not the “usual” DVD fare that may have disappointed you in the past.

The DVD starts by taking you through the features of a typical cast iron bandsaw, including those that are important to have and those you can do without. Hendrik reviews his Delta 14″ bandsaw, which has features in common with most cast iron designs. So as not to leave out viewers who own European cabinet style bandsaws, Hendrik also reviews his other bandsaw in great detail: his Laguna 16HD, which has many features in common with other European designed models. By focusing on both styles of bandsaw throughout the production, there is plenty of solid information for everyone, no matter what bandsaw you own.

After introducing you to the two bandsaw designs and their various features, Hendrik takes you through bandsaw blades and how to choose the right one. Importantly, he also teaches you how to fold a bandsaw blade, which is something all amateurs struggle with.

In Hendrik’s usual methodical way, he spends two full chapters taking you through various component upgrades that you might want to consider for your bandsaw, such as link belts, phenolic resin blocks, upgraded machined pulleys, etc. Then he takes you through various machinery checks and fine tuning to ensure your bandsaw is up to standard to do fine work.

An absolutely massive chapter takes you through blade changing and set-up, one step at a time. Again, this is covered for both bandsaw designs, including Delta’s 14″ cast iron model and Laguna’s 16 HD with its unique ceramic guide block system. Hendrik doesn’t leave any steps out, showing you how to set the blade tension, track the blade properly, set up the thrust bearings, guide blocks and so on. He explains blade drift and shows you a test to set your fence for optimum performance, even when resawing. This technical review teaches you everything you need to know about blade changing and fine set-up to squeeze out every bit of performance your bandsaw is capable of.

But Hendrik doesn’t stop at the technical set-up steps, taking you through another seven chapters on bandsaw use. He starts by taking you through general crosscutting and ripping techniques. As in his table saw DVD, “Revelations on Table Saw Set-up & Safety”, Hendrik takes you through the relevant safety rules for bandsaw use, even down to what each hand and finger is supposed to be doing. Importantly, there are distinct rule differences for the bandsaw compared to table saw technique and he takes you through those differences one rule at a time, while reminding you not to let your new bandsaw techniques affect the way you use the more dangerous table saw.

After covering general ripping and crosscutting techniques, Hendrik then spends a full chapter on the more demanding resawing tasks. He shows you how to make accurate resaws on his smaller cast iron machine, trying to get the most out of the 1 hp. motor. He also demonstrates taller resaws on the larger European model, which has the capacity to resaw over 16″ in height.

From there, Hendrik offers a separate chapter on free-hand curve cutting, including how to make tighter outside curves with a wider blade using relief cuts. A separate chapter covers circle cutting using a simple jig you will easily be able to build yourself. After cutting a perfect circle, you will be able to take that same jig over to your drill press and sand the edges of the circle with a sanding drum. Hendrik demonstrates this ingenious process of both cutting and sanding with the same jig.

Another full chapter is devoted to joinery, showing you some other great uses for your bandsaw. He shows you how your bandsaw can easily cut a full tail board for dovetails if you haven’t yet mastered the hand cutting techniques. He also demonstrates the cutting of a tenon to achieve a perfect fit in a mortise. He then teaches you how to cut a complete half-lap joint as well, showing you a simple but ingenious way to creep towards a tight final fit.

Hendrik is known for his extremely long and detailed “bonus footage” sections in his instructional DVD courses and this DVD is no exception. The bonus footage is called “Making Templates for Curved Furniture Parts”. He shows you the types of situations where he needs to make accurate templates in order to make curved furniture parts with the router. A very long chapter is spent discussing templates, showing you some simple tricks for drawing curves and showing you the whole process of bandsawing and sanding a template ready for use with your router. The router techniques themselves are beyond the scope of the bandsaw production, but are fully covered in the new router production also released in 2011.

In this must-have video, you will learn:

- how to choose a bandsaw, if you don’t already own one or are considering an upgrade

- how to inspect your bandsaw and find defects that are affecting its performance

- all about machinery component upgrades so that you can make your bandsaw perform better than how it was delivered from the factory

- how to fine tune the various components of your bandsaw to squeeze the best performance possible out of your machine

- how to properly tension a blade and track it

- how to properly set up the thrust bearings and guide blocks to ensure accurate and consistent cuts

- all about the various blades you can choose and how they will perform for regular cutting, resawing and curve cutting

- how to fold a bandsaw blade without losing five layers of skin in the process

- how to rip both rough stock and previously milled stock

- how to crosscut accurately using a mitre gauge

- how to resaw thick stock successfully and safely

- how to cut curves free-hand

- how to handle both inside and outside curves, and when to use relief cuts

- how to cut and then sand perfect circles using a simple jig you can build in minutes

- how to use your bandsaw to cut fine joinery and how to adjust the joinery for a finer fit

- all about templates and how they are used to make curved furniture parts

- about some of the tools used to draw curves on template stock

- how to draw on your template stock and cut just outside the lines with your bandsaw

- how to sand the template edges to perfection using a drum sander on a drill press and some careful hand sanding

As always, Hendrik’s DVD courses are not like the usual 45 to 60 minute production you may have found disappointing in the past. Hendrik takes you through every procedure in real time, ensuring that you fully understand the thinking behind every step. Most woodworking videos and television shows just show you the “gist” of each technique, editing away the finer details and problems that might arise. If you truly wish to elevate your bandsaw performance and techniques to a professional level, the details are everything.

Normally, Hendrik can only cover all of the high-level details he loves to teach in person, but he has once again succeeded at giving you personal coaching in a DVD format. As a 4-DVD boxed set running for nearly 8 hours, “Using and Tuning Your Bandsaw” will become the leading instructional woodworking DVD in this area. As the trademarked name says, this is “Private Woodworking Instruction in a Box” and nothing short of Hendrik’s in-shop seminars and courses even comes close.

To order your DVD today, click below.

Safety Discussion

Chapter 1

Cast Iron Bandsaws

Chapter 2

European Style Bandsaws

Chapter 4

Machinery Component

Upgrades

Chapter 6

Blade Changing

and Set Up

Chapter 8

Fine Ripping

and Crosscutting

Chapter 10

Free-hand Curve Cutting

Chapter 12

Joinery Work

Thoughts on

Woodworking

Part 1

Not a Finishing Tool

Thoughts on

Woodworking

Part 3

One Fussy Machine