Chapter 3

A Wood Milling Recap

Chapter 5

Milling and Crosscutting

the Final Blank

Chapter 7

Routing Chamfers and Flutes

Chapter 9

Jointing the Tapered Sides

Chapter 11

Bandsawing Leg Tapers

Chapter 13

Building My Leg Tapering Jig

Thoughts on

Woodworking

Part 2

Choosing the Right Tool for the Job

Instructional Woodworking

DVDs

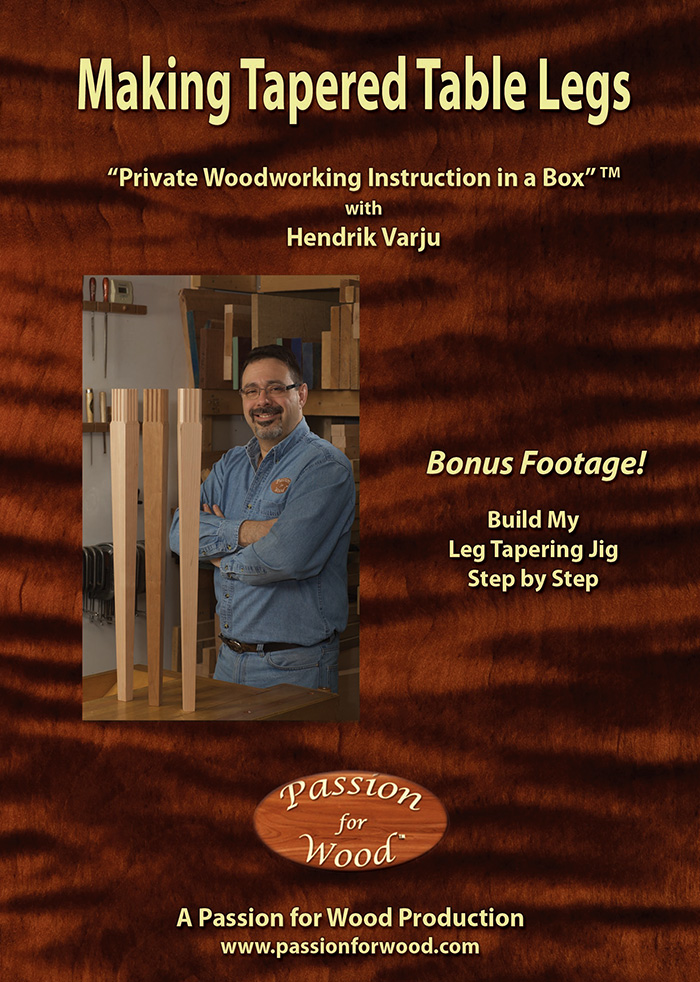

Making Tapered Table Legs

Author: Hendrik Varju

Hendrik Varju / Passion for Wood / August 2016

ISBN: 978-0-9881280-8-8

8 hours, 4 minutes on 4 DVDs

Price: Cdn. $94.95 + applicable taxes

+ shipping and handling

Ontario residents pay 13% hst. Canadian residents outside of Ontario pay hst at their own province’s rate, or 5% gst if in a non-participating province. Residents outside of Canada pay no tax.

To view a clip of this DVD click the play button above.

The above video clip has been reduced in quality for online viewing. The real DVD product has a much higher resolution.

![]()

To download a PDF of this production’s

Table of Contents click here.

This document will make it easier for you to navigate the video.

The Table of Contents is already included inside the DVD case, but you can download a copy here if you’ve misplaced it.

In 2016 Hendrik released two new instructional DVD offerings, bringing the total to 18 titles. “Finger Joints on the Table Saw” is the second DVD newly released in 2016, but let us first hear about the long awaited production: “Making Tapered Table Legs”.

Previous videos have covered machinery and tool skills, wood science, joinery methods, finishing and more. They have also covered how to build drawers and frame and panel doors. But this time Hendrik shows you how to make elegant tapered table legs, a signature element of many of his furniture designs. Coupled with previous DVD courses that teach you joinery methods, milling and edge gluing techniques, this new DVD set will allow you to build stunning tables, desks and other pieces of furniture. This production includes footage spread over more than 8 hours on 4 disks. As is Hendrik’s usual style, this DVD set is a detailed step-by-step course – not the “usual” DVD fare that may have disappointed you in the past.

The DVD starts by reviewing various types of tapered legs, including short tapers at the very bottom of some furniture legs or posts. Hendrik also goes over the various types of equipment you’ll need to make tapered table legs, such as jointer, planer, table saw, hand planes, routers and so on.

Chapter 2 covers the wood movement science and how it relates to gluing up leg blanks. If you ignore this information, you will build table legs that crack apart in future, so it’s critical that you learn how wood moves in relation to humidity changes and plan accordingly. Hendrik walks you through everything you need to know about making leg blanks that will survive intact.

In chapter 3, Hendrik reviews how to mill lumber to make table legs, including face jointing, edge jointing and then planing opposite edges and faces in the thickness planer. Hendrik’s first DVD production called “Jointer and Planer Secrets” covered these techniques in extreme detail, but in chapter 3 he gives you a quick overview as well.

Chapter 4 shows you how to glue up a leg blank, using C-clamps to keep the boards aligned and F-clamps to provide the main clamping pressure. He explains how many clamps to use and how to place them depending on the size of the leg blanks you’re making. Then chapter 5 shows you how to mill the glue-up to the final leg dimensions and cut to final length.

Chapter 6 offers an introduction to some joinery choices for table legs, with Hendrik cutting one mortise and drilling holes for dowels as a secondary method. Previous DVD sets have covered such joinery methods in greater detail, such as “Mortise and Tenon Joinery”, so he simply shows you how it is done without spending hours delving into every detail. The focus in this DVD production is show you how to build table legs, but Hendrik still wanted to briefly show you how joinery is incorporated into the process.

In chapter 7, Hendrik then shows you how to rout some beautiful decorative details at the top of a table leg. He starts with some small chamfers at the leg corners and finishes off with a set of three flutes on two sides of a leg. These are the kinds of details that can really elevate your work beyond the ordinary. Yet there are many pitfalls you need to avoid when working on these fine details on the router table, such as inaccurate measurements and burning.

Chapter 8 covers the actual leg tapering done with an ingenious leg tapering jig that Hendrik invented himself many years ago. Using this jig, he tapers a table leg on four sides, leaving a small amount of wood behind for final smoothing on a jointer. Chapter 9 covers the jointing method to bring the leg to its final taper in all its glory.

In Chapter 10, Hendrik shows you how to expertly sand a table leg, including sanding the small details like the chamfers and flutes. He shows you how to sand the tapers without rounding them over and without ruining the accurate joinery cut at the top. This is the kind of operation where “less is more”, so Hendrik takes you through his entire sanding regimen working from 120 grit up through 220.

In Chapter 11, Hendrik shows you how to cut similar leg tapers using a bandsaw instead of a table saw. This is required where table legs are larger and a table saw blade doesn’t have the height to cut through the leg in one pass. The same jig Hendrik uses for the table saw can be built for the bandsaw as well, but Hendrik shows you an even simpler method should you need to cut leg tapers only occasionally on the bandsaw.

Chapter 12 also shows you how to cut and hand plane very short tapers, such as you might find at the very bottom of a leg on a sideboard or some other case piece. His approach to the task is extremely simple, not requiring the building of any elaborate jigs. And it is always wonderful to watch Hendrik in action with a hand plane as well.

As in all of Hendrik’s DVDs, this production is full of techniques he has been using and perfecting for two decades. There is always a wonderful mix of theory, with sketches and full explanations, married with real-time demonstrations you can duplicate in your own workshop. This is the beauty of these multiple disk courses, which give you an absolutely enormous level of detail, but in a “live demonstration” format just not possible in a woodworking book or magazine article.

The most important aspect of this production, as with all the others, is Hendrik’s full demonstrations done in real time. He doesn’t assume prior knowledge, so even a beginner will be able to follow along the journey. Yet he has a knack for covering the basics while simultaneously delving into super fine points an amateur is unlikely to even consider for many years. The incredibly valuable lesson in all this is that Hendrik never just touches on the basics, but goes deeper, giving you a level of understanding of how to dial in accuracy on that last one one-thousandth of an inch. In fine furniture work, accuracy and detail is everything.

Hendrik is known for his detailed “bonus footage” sections in his instructional DVD courses and this DVD is no exception. The bonus footage is called “Build My Leg Tapering Jig Step by Step”. He designed and built a leg tapering jig many years ago and has since tapered hundreds if not thousands of legs with this design. His leg tapering jig was even featured on the front cover of Furniture & Cabinetmaking magazine in the UK in 2010. Hendrik’s approach to jig building has always been simplicity, keeping in mind that a jig is simply a means towards an end. The furniture building itself is always far more important than the jig itself, so jigs should be simple to make and pay big dividends compared to the effort required to build them.

The bonus footage on this DVD, comprising Chapter 13, runs for about 1.5 hours — longer than an entire woodworking TV show and even longer than most entire DVD productions. So you can be sure that Hendrik goes into every detail so that you can build his leg tapering jig in your own workshop. Most woodworking DVDs only run for 30 to 60 minutes, so Hendrik’s bonus footage always gives you a huge amount of new information not covered in the regular part of the production. Also, remember that Hendrik’s productions are not just “entertainment” like a woodworking television show. These are lengthy step-by-step woodworking courses in a DVD format. Like it says on the front cover of these productions, this is “Private Woodworking Instruction in a Box”TM. In short, “Making Tapered Table Legs” is the most complete DVD course of its kind on this subject matter. You’ll appreciate the depth of the information and the subtle details fleshed out at every opportunity.

In this must-have video, you will learn:

- about the different kinds of tapered table legs you can make, including two sided, four sided and even short tapers

- about the wood movement science you need to know to build leg blanks that will not crack or self-destruct over time

- how to use your jointer and planer to accurately mill the pieces needed to build leg blanks

- how to glue up leg blanks accurately and how many clamps to use

- how to mill the leg blank to final size and cut it to final length

- how to rout decorative chamfers and flutes on table legs with a router table

- how to cut leg tapers on a table saw using Hendrik’s own leg tapering jig design

- how to accurately smooth the tapers on a jointer to remove saw marks from the table saw

- how to sand a tapered table leg to perfection, including the fine details like chamfers and flutes

- how to cut tapers on a bandsaw when a table saw blade isn’t tall enough to cut through larger leg blanks

- how to cut and hand plane short tapers at the very bottom of some furniture legs or posts

- how to build Hendrik’s leg tapering jig, step by step

As always, Hendrik’s DVD courses are not like the more common 30 to 60 minute productions you may have found disappointing in the past. Hendrik takes you through every procedure in real time, ensuring that you fully understand the thinking behind every step. Most woodworking videos and television shows just show you the “gist” of each technique, editing away the finer details and problems that might arise. If you truly wish to elevate your leg tapering skills to a professional level, the details are everything.

Normally, Hendrik can only cover all of the high-level details he loves to teach in person, but he has once again succeeded at giving you personal coaching in a DVD format. As a 4-DVD boxed set running for over 8 hours, “Making Tapered Table Legs” will be the leading instructional woodworking DVD in this area. As the trademarked name says, this is “Private Woodworking Instruction in a Box” TM and nothing short of Hendrik’s in-shop seminars and courses even comes close.

To order your DVD today, click below.

Safety Discussion

Chapter 1

Types of Tapered Legs

& Required Equipment

Chapter 2

The Wood Movement Science

Chapter 4

Gluing Up the Leg Blank

Chapter 6

Time for Joinery

of Your Choice

Chapter 8

Using My Leg Tapering Jig

Chapter 10

Sanding the Leg

Chapter 12

Cutting and Hand Planing

Short Tapers

Thoughts on

Woodworking

Part 1

The Importance of Wood Science

Thoughts on

Woodworking

Part 3

Multifunctional Jigs are Smart

Safety Discussion

Chapter 4

Gluing Up the Leg Blank

Chapter 8

Using My Leg Tapering Jig

Chapter 12

Cutting and Hand Planing

Short Tapers

Thoughts on

Woodworking

Part 3

Multifunctional Jigs are Smart

Chapter 1

Types of Tapered Legs

& Required Equipment

Chapter 5

Milling and Crosscutting

the Final Blank

Chapter 9

Jointing the Tapered Sides

Chapter 13

Building My Leg Tapering Jig

Chapter 2

The Wood Movement Science

Chapter 6

Time for Joinery

of Your Choice

Chapter 10

Sanding the Leg

Thoughts on

Woodworking

Part 1

The Importance of Wood Science

Chapter 3

A Wood Milling Recap

Chapter 7

Routing Chamfers and Flutes

Chapter 11

Bandsawing Leg Tapers

Thoughts on

Woodworking

Part 2

Choosing the Right Tool for the Job